The Paradox of Automation: when too much efficiency becomes inefficient

How over-reliance on automated systems can amplify risks, erode expertise, and introduce hidden costs. Discover strategies to balance efficiency with adaptability and ensure technology empowers rather than controls your organization.

OPERATIONS

Alessandro

12/16/20243 min read

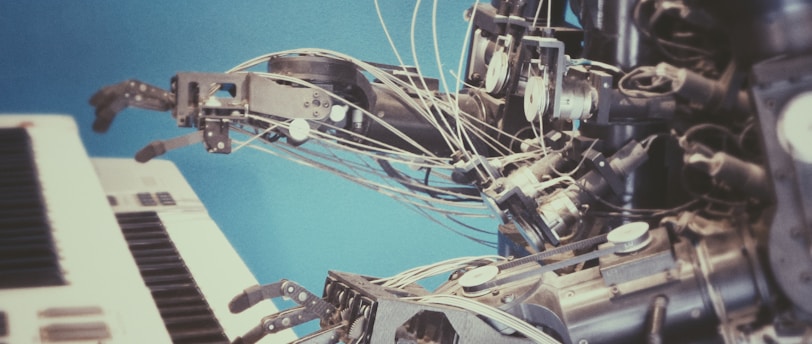

Automation is hailed as the panacea for operational inefficiencies, promising to streamline processes, reduce costs, and increase productivity. Yet, like any powerful tool, it comes with risks. The paradox of automation reveals a counterintuitive truth: when organizations rely too heavily on automated systems, they may inadvertently create new inefficiencies and vulnerabilities. This nuanced challenge demands thoughtful leadership and strategic oversight to harness automation’s potential without falling into its traps.

Let’s explore how this paradox manifests, its implications for modern operations, and strategies to strike the right balance.

What is the Paradox of Automation?

Coined by experts in systems theory, the paradox of automation describes the phenomenon where increasing automation can:

Amplify Errors: Automated systems execute processes at high speed and scale. If these processes contain flaws, automation magnifies the impact of those flaws exponentially.

Erode Human Expertise: As tasks are delegated to machines, employees lose the opportunity to develop and maintain critical skills, leaving organizations vulnerable in moments of system failure.

Introduce Hidden Costs: Automation may reduce direct labor costs but can introduce hidden expenses, such as system maintenance, troubleshooting, and unforeseen disruptions.

This paradox challenges the assumption that automation is an unequivocal good. Instead, it underscores the importance of balancing efficiency with resilience and adaptability.

Case Study: the automated trading meltdown

In 2012, Knight Capital, a leading financial services firm, suffered a catastrophic $440 million loss in 45 minutes due to a software glitch in its automated trading system. The issue stemmed from a lack of oversight and human intervention capabilities, highlighting the dangers of over-reliance on automation in high-stakes environments.

Key Takeaway: Automation without robust monitoring mechanisms and fail-safes can lead to disproportionate risks. Leaders must ensure that human oversight is an integral part of automated processes.

Risks of Over-Automation in Operations

1. Fragility in Crisis

Highly automated systems are often designed for predictable conditions. In the face of unexpected disruptions, these systems may fail spectacularly, as they lack the flexibility and intuition of human operators.

Example: During a supply chain disruption caused by extreme weather, FedEx experienced delays in package routing due to over-reliance on automated systems. Manual intervention, no longer a widely practiced skill among employees, resulted in significant inefficiencies and costly delays.

2. Loss of Institutional Knowledge

Automation can create a skills gap by eroding employees’ hands-on expertise. When systems malfunction, teams may lack the knowledge to address issues effectively.

Example: Tesla's Gigafactory faced prolonged downtime when its highly automated battery production line encountered software malfunctions. The lack of technicians with the required expertise to address these issues quickly resulted in costly delays in production.

3. The Hidden Cost of Maintenance

Automation often reduces visible labor costs but introduces significant, less obvious expenses related to:

System updates and upgrades.

Cybersecurity measures.

Specialized training for maintaining automated systems.

Example: Walmart adopted a fully automated inventory management system that, while reducing direct labor costs, incurred unexpectedly high expenses for software licensing and cybersecurity, ultimately surpassing initial savings projections.

Strategies to manage the paradox

1. Design for Hybrid Operations

Automate tasks while retaining human oversight for critical decision points. Hybrid systems combine the strengths of automation with human adaptability.

Action Step: Implement systems that allow employees to intervene and override automated processes when necessary.

2. Invest in Human Expertise

Prioritize training programs to ensure employees maintain the skills needed to complement and back up automated systems.

Action Step: Regularly rotate employees through manual operations to preserve institutional knowledge and build resilience.

3. Build Redundancy into Automated Systems

Redundancy ensures that a single point of failure doesn’t bring operations to a standstill.

Action Step: Establish parallel systems and manual fallback procedures for mission-critical processes.

4. Conduct Scenario Planning

Anticipate potential failures and test responses to ensure systems and teams are prepared for crises.

Action Step: Host regular tabletop exercises to simulate disruptions and refine contingency plans.

Automation as a tool, not a replacement

The paradox of automation reminds leaders that efficiency must never come at the expense of adaptability and resilience. While automation has the power to transform operations, it is not a substitute for human expertise and strategic foresight.

To thrive in today’s complex environments, leaders must:

Balance efficiency with adaptability.

View automation as a complement to, not a replacement for, human capabilities.

Proactively address the risks and hidden costs of over-automation.

In the end, the most effective organizations are those that leverage automation as a tool for empowerment—not a crutch for dependency.

Because in a world driven by technology, it is still the human touch that ensures lasting success.